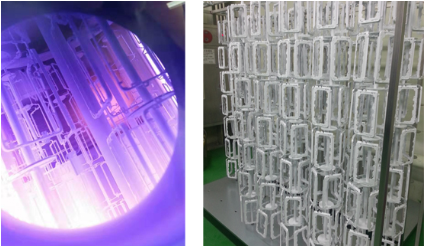

PVD (Al) Coating System

PVD (Al) Coating System

PVD(铝)镀膜系统

- AF Coating System

- AR & Multilayer Coating System

- E-beam Coating System

- PVD (Ceramics) Coating System

- PVD (Al) Coating System

- Spray AF Coating System

- AF Coating System

- AR & Multilayer Coating System

- E-beam Coating System

- PVD (Ceramics) Coating System

- PVD (Al) Coating System

- Spray AF Coating System

본설비는 스퍼터링 방식으로 다이캐스팅소재, SUS, Mg, PEAK등 소재 표면에 Al코팅하는 설비 입니다.

This equipment uses the sputtering method to apply aluminum coatings on the surfaces of materials such as die-cast alloys, SUS, Mg, and PEEK.

本设备为采用磁控溅射方式在压铸合金, SUS, Mg, PEAK等产品表面上形成铝金属薄膜的设备.

Application

Al코팅 가능한 제품(다이캐스팅, SUS, Mg, PEAK등) 소재에 아노다이징 기술을 적용하여 다양한 칼라 구현.

By applying anodizing technology to materials suitable for aluminum coating (such as die-cast alloys, SUS, Mg, and PEEK), a variety of colors can be achieved.

可镀铝的材质(压铸合金, SUS, Mg, PEAK等)上使用阳极氧化技术, 呈现多样色彩和华丽外观.

Features

- 턴 테이블 공,자전으로 박막 균일성과 생산성 최대화

- Capa. : [143×73×5T] 448EA / Batch

- Batch Time : 210min

- Forming uniform thin film and high production by using rotative and orbital jig.

- Capacity : [143×73×5T] 448EA / Batch

- Batch Time : 210min

- 采用公转/自转治具形成均匀的薄膜, 生产量极大化

- Capacity : [143×73×5T] 448EA / Batch

- Batch Time : 210min

Spec

| Description | Spec. | Etc. | |

|---|---|---|---|

| BODY | Vacuum Chamber |

W1,250 L1,250×H1,600 |

|

| Deposition module | Sputtering | ||

| Planetary jig module | 16 Axis | ||

| VACUUM PUMP | Oil diffusion pump | 28”, 1Set | 5.0×10-5 torr ↓ |

| Oil rotary & booster pump | SV630B & WSU2001 | ||

| Control System | AUTO Mode | ||

| OPTION | Chiller | 75 RT | |

| Floor Area | L6,500×D6,500×H3,000 | Weight / 5.0t | |