AF Coating System

AF Coating System

AF 镀膜系统

- AF Coating System

- AR & Multilayer Coating System

- E-beam Coating System

- PVD (Ceramics) Coating System

- PVD (Al) Coating System

- Spray AF Coating System

- AF Coating System

- AR & Multilayer Coating System

- E-beam Coating System

- PVD (Ceramics) Coating System

- PVD (Al) Coating System

- Spray AF Coating System

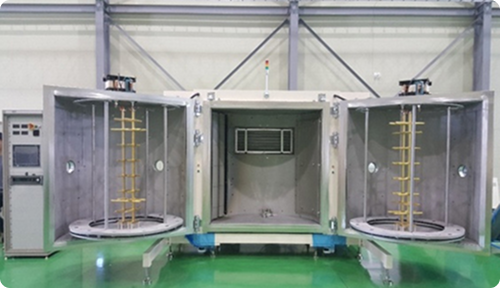

본 설비는 SPUTTERING방식으로 제품 표면에 박막 코팅을 진행하고 밀착력을 높이며 Thermal Evaporation방식으로 불소화합물을 코팅하여 제품표면에 내지문코팅을 진행하는 설비입니다.

This equipment is a sputtering machine that forms a thin film on the product surface to enhance adhesion. Using thermal evaporation, it deposits a fluorine-based compound, providing an anti-fingerprint coating.

本设备是在产品表面上通过SPUTTERING方式形成薄膜,从而提高密着性,再以Thermal Evaporation方式在产品表面上镀氟化合物,使产品表面上形成耐指纹的设备。

Application

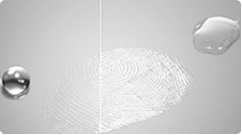

스마트 폰,태블릿 PC등 커버 글라스표면에 내지문 효과

Anti-fingerprint effect on the cover glass surface of Smartphone, tablet PCs, and other devices

智能手机,平板电脑等钢化玻璃表面上做耐指纹镀膜

Features

- 턴 테이블 공,자전으로 박막 균일성과 생산성 최대화

- 습식 방식 대비 원자재 원가 절감, E-Beam 대비 생산효율 향상(4~6배↑)

- Capa. : 432EA/Batch in size of 7 inch

- Process Time : 40min

- Uniform thin film formation and maximized productivity using rotary and orbital jigs

- Reduced material costs compared to the wet process, and 4–6 times higher production efficiency compared to the E-beam method

- Capacity : 432 units per batch (7-inch size)

- Process Time: 40min

- 采用公转/自转治具形成均匀的薄膜, 生产量极大化

- 涂方式对比原材料成本降低(AF药品) 以及 E-Beam方式对比提 高生产量(4~6倍↑)

- Capacity: 432EA/Batch in size of 7 inch

- Process Time : 30min

Spec

| Description | Spec. | Etc. | |

|---|---|---|---|

| BODY | Vacuum Chamber | Φ1600×1600H | |

| Deposition module | Sputter + Evaporation | ||

| Planetary jig module | Φ280 × 12 Axis | ||

| VACUUM PUMP | Oil diffusion pump | 24”, 2Set | 5.0×10-5 torr ↓ |

| Oil rotary & booster pump | SV630B & WSU2001 | ||

| Control System | AUTO Mode | ||

| OPTION | Chiller | 20RT | |

| Poly cold | 100,000ℓ/sec | ||

| Floor Area | L4500×D6500×H2300 | Weight / 4.5t | |